Backflow Prevention Device Guide for Homes and Businesses

A backflow prevention device protects your drinking water by stopping contaminated water from reversing direction inside your plumbing system. When backflow occurs, dirty water from an irrigation system, sewer line, ground runoff, or cross connections can flow backwards into clean supply lines. (more…)

Commercial Plumbing Maintenance: Complete Guide for Facilities

Commercial plumbing maintenance is one of the most important steps in keeping a commercial plumbing system functioning properly, especially in high-traffic environments where plumbing systems support hundreds of building occupants each day. Whether you manage an office, restaurant, multi-family property, retail center, or healthcare facility in Fairfield County, CT, or Westchester County, NY, preventative maintenance is essential. (more…)

Sump Pump Maintenance Guide for CT and NY Homeowners

Basements in Connecticut and New York face constant risks from heavy rain, storms, and rising groundwater. When the water level reaches the bottom of the sump pit, the entire system relies on a properly maintained sump pump to begin removing water before it causes flooding or structural damage. (more…)

Complete Home Plumbing Inspection Checklist for 2026

A home plumbing inspection checklist helps homeowners catch leaks, slow drains, water pressure issues, and early damage inside plumbing systems before costly repairs occur. Whether you live in Fairfield County, CT, or Westchester County, NY, a full home plumbing inspection allows you to assess sinks, toilets, pipes, faucets, and valves to ensure everything is functioning properly. (more…)

Average Cost to Replace Water Heater in 2026

The average cost to replace a water heater varies based on the type of system you choose, the installation requirements, and the condition of your current water heater setup. Homeowners across Fairfield County, CT, and Westchester County, NY often need fast answers when they experience leaks, strange noises, sediment buildup, or inconsistent hot water. (more…)

How to Fix a Leaky Faucet: Simple Steps Any Homeowner Can Do

A leaky faucet may start as a small annoyance, but those constant drips add up quickly. Even a slow leaking faucet can waste thousands of gallons each year, raise your water bill, and create moisture damage around your sink, countertop, or bathroom fixtures. (more…)

Priming a Well Pump: Step-by-Step Guide for CT Homeowners

A loss of water pressure can disrupt everything from morning showers to basic cleaning, and one of the most common reasons is a well pump that has lost its prime. For many homes across Connecticut and Westchester County, a well water pump is the heart of the water system, quietly keeping a steady water supply moving from underground into the house. (more…)

Well Pump Lifespan: How Long They Last

A well pump is the unsung hero of your home’s water system. It quietly pulls fresh water from underground aquifers and delivers a consistent supply to your faucets, showers, and appliances every day. Because the well pump operates behind the scenes, many homeowners don’t think much about how long a well pump lasts until they notice low water pressure, strange noises, or a sudden decrease in flow. (more…)

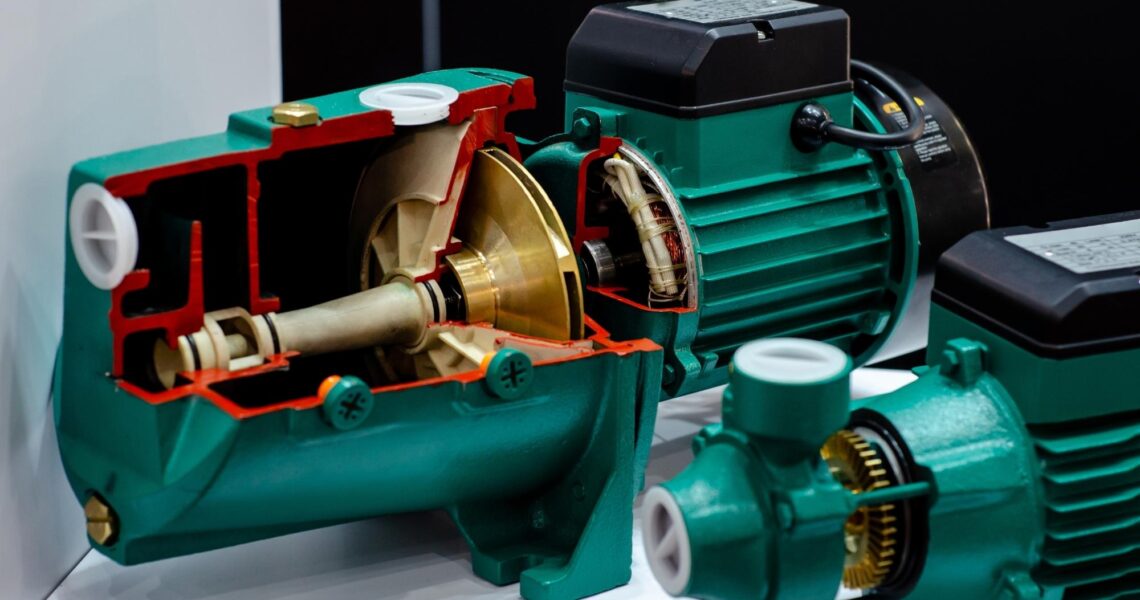

Deep Well Pump vs Shallow Well Pump Comparison

If your home relies on a well for a clean water supply, choosing between a deep well pump and vs shallow well pump is one of the most important decisions you’ll make for the health of your plumbing system. The right pump system affects everything from water pressure, energy efficiency, and flow rates to how your home performs during dry seasons. (more…)

Complete Well Pump Maintenance Guide for Homeowners

A dependable well pump system ensures your home’s water supply stays clean, steady, and reliable year-round. Without regular well pump maintenance, small issues like corrosion, mineral buildup, or faulty wiring can lead to major system failures that disrupt your access to drinking water. Proper pump maintenance keeps every component, from the pressure tank to the pressure valve, working efficiently and safely. (more…)